Introduction to the U5A target

The U5A eScore target is a next generation electronic target based on acoustic scoring. It works well with supersonic ammunition and is designed to be placed at 100-300 meter rifle ranges, though not limited to these distances. These kind of targets (s.k. U-targets) have all electronics and sensors placed at the bottom of the target, making it extremely robust when placed correctly (behind a berm or protective plates).

Features of the U5A target

- 3 acoustic sensors, all placed at the bottom of the target.

- Wide range of target faces and target definitions are available.

- Guide pin design allows swift change of target face, without need for additional zero point adjustment.

- Can be used with a wide range of supersonic calibers - from .223 to .338LM and more.

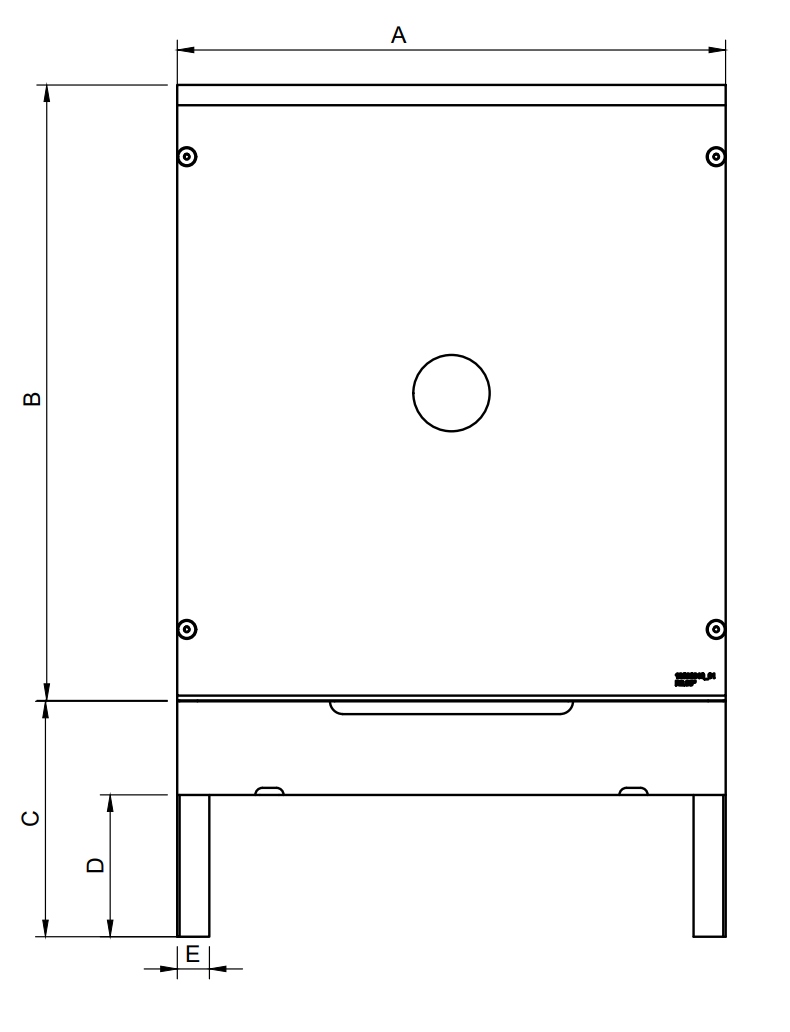

Technical specifications and dimensions

A |

1300 mm |

|

B |

1300 mm |

|

C |

500 mm |

|

D |

300 mm |

|

E |

68 mm |

|

F |

36 mm |

|

G |

92 mm |

|

H |

Max 164 mm |

| Temperature range | -30 to +60 °C |

| Weight | ~ 30 kg |

| Power consumption | ~ 4 W @ 24 VDC |

| Calibers | Supersonic projectiles |

Exploded view and parts list

A-target configurations

| Item | Part name | KTS part no. |

| 1 |

The target → Target U5A - eScore → Target H3A - eScore |

13020313 13020177 |

| 3 | Main target rubber skin (2pcs pr target) | 97020540 |

| 6 |

Guide pins (4pcs pr target) → threaded centre → non threaded centre → headed, non threaded center |

97020728 97020850 97020845 |

| 7 | Front temperature shield |

Several available See table below |

| 8 | Foam sheet insert |

Several available See table below |

| 9 | Rear temperature shield | 13020103 |

| 10 | Target face |

Several available See table below |

| 11 | Fixation nut (8pcs pr target) | 97020729 |

| 14 | Male I/O cable |

Amphenol: 13020209 M23: 13020190 |

| 15 | Female I/O cable |

Amphenol: 13020210 M23: 13020191 |

| 16 | Horizontal rubber band |

97020895 (60cm wide) 97020547 (46cm wide) |

| 18 | Top cover | 97020527 - 130cm |

Front temperature shields available

Abbr. part name |

KTS part no. |

Target setup no. |

Image |

P30A |

13020133 |

#1 |

|

P40A |

13020104 |

#2 |

|

P50A |

13020106 |

#3 |

|

P60A |

13020243 |

#4 |

|

Foam sheet inserts available

| Abbr. part name | KTS part no. | Fits target setup no. |

| FS 30x30/35x35 | 13020155 | #1 |

| FS 40x40/50x50 | 13020158 | #2 |

| FS 50x50/60x60 | 13020159 | #3 |

| FS 60x60/70x70 | 13020154 | #4 |

| FS 60x60/120x80 | 13020213 | #4 |

Target faces available

| Abbr. part name | KTS part no. | Fits target setup no. | Fits target scoring definition no. |

| R13'' | 13020081 | 1, 2, 3, 4 | 369 |

| R19'' | 13020082 | 3, 4 | 370 |

| R6.35'' | 13020130 | 1, 2, 3, 4 | 372 |

| 1/10-fig | 13020226 | 1, 2, 3, 4 | 155 |

| C20-fig | 13020227 | 1, 2, 3, 4 | 278 |

| C25-fig | 13020228 | 1, 2, 3, 4 | 350 |

| 1/8-fig | 13020229 | 2, 3, 4 | 348 |

| (10/30)-fig | 13020230 | 1, 2, 3, 4 | 353 |

| (30/10)-fig | 13020231 | 1, 2, 3, 4 | 277 |

| ⅓-fig | 13020232 | 3, 4 | 38 |

| R20 | 13020250 | 1, 2, 3, 4 | 7, 77, 169, 269 |

| R60 | 13020251 | 4 | 3, 6, 21, 196, 217, 288, 295 |

| R8'' | 13020277 | 1, 2, 3, 4 | 123, 378, 379, 384, 413 |

| R11 ¾'' | 13020278 | 1, 2, 3, 4 | 426 |

| ¼-fig | 13020280 | 2, 3, 4 | 39 |

| 1/4V-fig | 13020281 | 2, 3, 4 | 429 |

| C30-fig | 13020282 | 2, 3, 4 | 40 |

| 1/6-fig | 13020283 | 4 | 279 |

| S25H-fig | 13020284 | 4 w/13020213 | 351 |

| (13/40)-fig | 13020285 | 2, 3, 4 | 276 |

| (40/13)-fig | 13020286 | 2, 3, 4 | 352 |

| S25V-fig | 13020287 | 4 w/13020213 | 356 |

| Småen-fig | 13020297 | 1, 2, 3, 4 | 113 |

| IPSC V2/A | 13020298 | (*Note 2) | 440 |

| R24 | 13020304 | 1, 2, 3, 4 | 1, 92 |

| R40 | 13020305 | 2, 3, 4 | 2, 4, 170, 399 |

| B45-fig | 13020319 | 2, 3, 4 | 354 |

| C40-fig | 13020320 | 2, 3, 4 | 357 |

| Sirkel-fig | 13020321 | 1, 2, 3, 4 | 79, 349 |

| Tønne-fig | 13020322 | 1, 2, 3, 4 | 164 |

| Blank | 13020387 | 1, 2, 3, 4 | All (*Note1) |

| C15-fig | 13020388 | 1, 2, 3, 4 | 156 |

| P-Fig | 13020397 | 1, 2, 3, 4 | 453 |

| D-Fig | 13020398 | 1, 2, 3, 4 | 452 |

| Fiskebeck | 13020416 | 4 w/13020213 | 447 |

| Mini P-fig | 13020417 | 1, 2, 3, 4 | 450 |

| Mini 1/9-fig | 13020418 | 1, 2, 3, 4 | 448 |

| Dråpe-fig | 13020419 | 1, 2, 3, 4 | 449 |

| 1/9-fig | 13020420 | 1, 2, 3, 4 | 451 |

| Reindeer | 13020345 | 1, 2, 3, 4 | 64 |

| Running (Norwegian siam) moose | 97060013 |

1, 2, 3, 4 (Note 3) |

30 |

Note1: This target face is all-white and may be fitted with any target figures by customer.

Note2: This target face is black. White spot is intended, by adding white contrast sheet (KTS part no: 140205409).

Note3: Need target extension.

Dismantlig

See exploded view figure above.

Target assembly must be partly disassebled when doing maintenance. Top cover is attached to target with Velcro, and is simply pulled up to be picked off. Other parts can be picked off after unscrewing guide pin nuts.

U target disassembly

...

Target maintenance

Replacement or rotation of rubber band. Replacing foam sheet inserts.

The rubbers at target is worn by penetrating projectiles. This will eventually cause noise to enter the soundproof measuring chamber inside the target.

Such wear normally occurs in the center of the target. To ease maintenance and lower maintenance cost the target is fitted with a rubber band and a foam sheet insert that is covering the centre of the target.

This rubber band must cover the hole, pre-cut or later cut out, of the target rubber skin. The rubber band is intended to be rotated sideways to eliminate the wear at centre. When rubber band is rotated, the foam sheet should also be replaced.

How often this maintenance is needed depends on calibres in use, bullet shapes, shooting distance and shooter skills (grouping). As a rule of thumb, for this target model, we recommend following intervals based on shooting distance:

| Shooting distance: | Maintenance intervals: |

| 100m/yds | Every 400 shots |

| 200m/yds | Every 1500 shots |

| 300m/yds | Every 3000 shots |

Note that the table above assumes normal full jacketed bullets and relatively good groupings. If groupings are larger the intervals can be even longer. The use of hunting ammunition may call for more frequent maintenance.

The splice of the rubber band should always be kept at the back of the target. Avoid having the splice at center of target, until the last leg of the rubber band is used.

The rubber band need to be rotated approximately ½ of the diameter of the cut-out section of the front target rubberskin (leaving fresh rubber at center), if the rubber band isn't worn excessively. For a new target, this would be approcimately 20cm (8'').

When the rubber band eventually is rotated ½ roud, it needs to be replaced with a new one. In this event, the upper guide pins need to be removed before putting the new rubber band at target. Soap in spray bottle might be helpful when replacing rubber band, to reduce friction.

VIDEO

NOTE!

Ensure that the rubber band is put tightly against the target rubber skin.

Please note that the scoring system has shot counters that may be reset when doing maintenance - to keep track of shot numbers.

U-Target inspection

Repair ricochet damages to target rubber skin

In the event of projectiles passing through the target as they are tilted or otherwise deformed, they may generate large holes in the target rubber skins.

If the large holes occur in the X-rubber, scoring issues are prevented by exchanging it.

If the large holes occur at the main target rubber skin, outside the X-rubber, the holes need to be patched. This is done by spray glue and a piece of adhesive tape, or fast curing super glue and a piece of rubber.

Inspecting the target rubber skin

The target rubber skin need to be replaced in these events:

| 1. |

Excess wear (large number of shot holes) at target rubber skin will affect scoring accuracy. This is especially important at the edge of the cut-out of the target rubber skin. This phenomena is particularly bad when the rubber sheet doesn't hold together, and coin sized parts start dangling.

If edge of cut-out is poor, as described above, the size of the cut-out may be increased by use of scissors. However, it is outmost important that the rubber band still is covering the cut-out with good margins (3-4cm). |

| 2. | As the target rubber skin is aging, its tensile strength will degrade. The target measuring chamber (between the target rubber skins) may eventually implode if the target is subjected to wind. Implosions can be temporarily be fixed by detaching, stretching and reattaching the target rubber skin. |

| 3. | As the target rubber skin is aging, it will eventually start to crack. Cracks may become holes and compromise the sound proof measuring chamber. |

Cleaning sensors

Rubber particles and debris will fall to the bottom of the target. Some will pile at the sensors.

It is recommended to clean the sensors at 3000 shots intervals, or before competitions. Cleaning is done with a soft brush, brushing off particles at the sensor heads.

Warning!

Do not use excess forse when brushing, thus dislocating the sensors.

Target service panel at the bottom of the target need to be opened to access the sensors (sensor bar). To open the service panel, FX target face and (lower) temperature shield first need to be removed from target. Also two rubber straps at the hatch need to be taken off. Please remember to put them back after cleaning.

Inspecting the target face

Target faces are worn by penetrating projectiles. They should be replaced if they provide a poor target profile for the shooter. Fixation nuts (at front of the target) must be taken off before replacing target face - if they are not attached with velcro (see parts list).

Inspecting the target service panel

The lower part of the target has a service panel that can be opened to access the target electronics and the lower sensors. Opening and closing is done by operting the white rubber straps at the bottom of the target.

Inspect the physical integrity of the service panel and its hinges/straps, and check that it's possible to close completely. There should be no cracks that sound can “leak” through when the service panel is closed. Always keep the service panel closed and strapped, expect when servicing or inspecting the internals of the target.

Inspecting and replacing the temperature shields

The temperature shields task is to obtain an even temperature inside the target, even if the target is exposed to sunlight. The temperature shields are also worn by the projectiles. Typically the rear temperature shield is worn in the centre section.

| Rear temperature shield will start swelling after a few hundread rounds. |  |

| To awoid collapse of measuring chamber, the rear temperature shield is fitted with a a rip-off section. |  |

| Rip off when rear temperature shield start swelling, and put the temperature shield back at target with the rip-off section facing target rubber skin. |  |

Expect to replace rear temperature shield when the hole has a diameter of 40cm (15'').

The temperature shields are also worn by sunlight and other environmental factors. Expect to replace when the temperature shields doesn't maintain physical integrity.

Target repairs

I/O cable repairs

Target I/O cables, at the bottom of the target, can easily be replaced when the front target service panel is opened. The I/O cables have connectors at both ends, one for connection to the scoring system, and one for connection to the target electronics inside the target.

I/O cables are lead through a track in the target frame, and put in a loop just inside the target frame. They are attached to the taget frame with duct tape, cable ties and cable clips. Make sure that the cable loop doesn't touch the nearby sensor.

Protection of the U5A target

How to protect the U5A target from stray bullets and ricochets

Protecting the eScore acoustic target

The eScore targets have the critical electronics located at the bottom of the tar

The targets have the most critical, or all, electronic components located at the bottom of the target - behind the service panel. To minimize maintenance cost and maintain the target durability it is recommended to protect this section of the target by use of a knee wall or protective plates. Target stands with protective plates are available on request.

Please refer to this YouTube video for recommendations on how to install the targets.

Protection from ricochets and shrapnel

Some shooting ranges have backstop that create shrapnel when bullets hit bullet catchers. This should be avoided since cables may be cut or short circuited by shrapnel or bullet jackets. To minimize the effects careful placement of the wiring between targets, antennas, batteries etc. must be done. If steel bullet catcher is used, make sure to cover it with rubber material or other absorbent material to minimize ricochets and shrapnel exiting the bullet catcher.