Introduction to H3H

The H3H eScore target is a next generation electronic target based on acoustic sensors. It works with supersonic ammunition, but will detect projectiles even as they go subsonic. It is designed to be used for 200-600 m/yds shooting ranges, particularly suited for long range shooting.

Features of the H3H target

- 4 acoustic sensors, one in each corner of the target, for optimal scoring accuracy

- Closed chamber acoustic detection system, unaffected by weather conditions.

- Several different target faces available.

- Guide pin design allows swift change of target face, without need for subsequent zero point alignement.

Technical specifications and dimensions

A |

1822 mm |

|

B |

1822 mm |

|

C |

550 mm |

|

D |

100 mm |

|

E |

68 mm |

|

F |

36 mm |

|

G |

92 mm |

|

H |

155 mm |

| Temperature range | -30 to +60 °C |

| Weight | ~ 76 kg |

| Power consumption | ~ 4.4 W @ 24 VDC |

| Calibers | Primarily intended for supersonic projectiles like .223, .308, 30-06, 6.5mm, 6mm, but will detect projectiles even as they go subsonic. |

Exploded view and parts list

Below is an exploded view of the components used for the H3H eScore target.

| Item | Product name | KTS part no. |

| 1 | Target model H3H | 13020167 |

| 3 | Guide pin nuts (12pcs) | |

| 4 |

FX target face → Ø36'' → Ø36'' with velcro → FC 1000yd (printed) → Ø19'' → Ø13'' → Ø6.35'' → Ø60cm → USMC Threat Halo (printed) → USMC Dog Target (printed) |

- 13020083 13020201 13020265 13020162 13020163 13020173 13020301 13020289 13020318 |

| 5 | P100 temperature shield | 13020114 |

| 6 | Top cover | 97020351 |

| 7 | P00 temperature shield (rear) | 13020113 |

| 8 |

Guide pins (6pcs) → threaded centre → non threaded centre → headed, non threaded |

- 97020728 97020850 97020845 |

| 9 | Small temperature shields (2pcs) | 13020112 |

| 10 |

Female I/O cable → Amphenol → M23 |

- 13020210 13020191

|

| 11 |

Male I/O cable → Amphenol → M23 |

- 13020209 13020190 |

| N/I | Vertical rubber band (100cm) | 97020444 |

Target rubbers

|

The target is fitted with a target rubber skin (both at the front of the target frame and at the back) and a rubber band to obtain a soundproof measuring chamber in between. The target rubber skins are also fitted with a Ø600mm hole in the centre section, to reduce wear affecting scoring accuracy.

|

|

To keep a sound proof measuring chamber and ease maintenance the target is fitted with a rubber band. The rubber band roll is basically put in front of the target, pulling one end up at the front of the target and down at the back - between the target skin and the inside of the temperature shields. The cut-outs need to be completely covered by the rubber band.

|

|

Disassembly

See exploded view figure above.

Target assembly must be disassembled when doing maintenance. Top cover is attached to target with Velcro, and is simply pulled up to be picked off. Other parts can be picked off after unscrewing guide pin nuts.

H3H target maintenance

Moving the rubber band

The target is worn by shooting. To obtain a sound proof measuring chamber the vertical target rubber band need to be moved at certain intervals. These intervals are affected by shooter skills (grouping), calibers in use and bullet shapes. As a rule of thumb we recommend rotating the rubber band with following intervals:

| Shooting range | Rotation after this number of shots: |

| 200yds/m | After 1500 rounds |

| 300yds/m | After 2500 rounds |

| 600yds/m | After 3000 rounds |

The main target rubber skin has a center cut-out of approximately Ø60cm (24''). Rubber band should be rotated approximately ½ of this hole size → 30cm (12''), unless excessively worn.

Please note that the scoring system has shot counters that may be reset when doing maintenance - to keep track of target wear.

Please also note that when moving the rubber band, the wear of the rubber band (at front side of the target) eventually will end up at the back of the target. That does not affect scoring accuracy unless target rubber band is excessively worn. This is true as the qualty of the target rubber at the front of the target is more important than at the back of the target.

Repair ricochet damages to target rubber skin

In the event of projectiles passing through the target as they are tilted sideways or otherwise deformed, they may generate large holes in the target rubber skins.

If the large holes occur in the target rubber band, scoring issues are prevented by rotating the rubber band in a way that the holes are covered by the main rubber skin (not being in the cut-out zone of the target rubber skin. See figures above.

If the large holes occur at the main target rubber skin, outside the area that is covered by the rubber band, the holes need to be patched. This is done by spray glue and a piece of adhesive tape, or fast curing super glue and a piece of rubber.

Inspecting the target rubber skin

The target rubber skin need to be replaced in these events:

| 1. | Excess wear (large number of shot holes) at target rubber skin will affect scoring accuracy. This is especially important at the edge of the cut-out of the target rubber skin. This phenomena is particularly bad when the rubber sheet doesn't hold together, and coin sized parts start dangling. |

| 2. | As the target rubber skin is aging, its tensile strength will degrade. The target measuring chamber (between the target rubber skins) may eventually implode if the target is subjected to wind. Implosions can be temporarily be fixed by detaching, stretching and reattaching the target rubber skin. |

| 3. | As the target rubber skin is aging, it will eventually start to crack. Cracks may become holes and compromise the sound proof measuring chamber. |

Inspecting the sensor cables

Sensor cables are put at the outside edge of the target frame (left and right side). Inspect the outer 10mm of the target frame to see if any stray projectiles possibly has penetrated and possibly snatched any cables. If so, the sensor cables can be picked out of the cable track to be investigated. Sensor cables should be repaired according to the “Target repairs” chapter if the outer sheath of a cable is compromised. A damaged cable can be electrically functional, but be affected by moisture over time, and should therefore be fixed.

Inspecting the target face

Replace target face when the aiming mark visual definition is getting unclear for the shooter. Shooters with scopes will probably require high quality of the target face.

Inspecting and replacing the temperature shields

The temperature shields task is to obtain an even temperature inside the target, even if the target is exposed to sunlight. The temperature shields are also worn by the projectiles, leaving a larger hole in the centre sections.

Expect to replace temperature shields when the hole has a diameter of 40cm (15'').

The temperature shields are also worn by sunlight and other environmental factors. Expect to replace when the temperature shields doesn't maintain physical integrity.

Inspecting the target service panel

The lower part of the target has a service panel that can be opened to access the target electronics and the lower sensors. Opening and closing is done by operting the white rubber straps at the bottom of the target.

Inspect the physical integrity of the service panel and its hinges/straps, and control that it's possible to close completely. There should be no cracks that sound can “leak” through when the service panel is closed. Always keep the service panel closed and strapped, expect when servicing or inspecting the internals of the target.

Target repairs

Repairs

Repairing sensors or wiring

Whenever an H-target model is used, one runs the risk of a shooter hitting the up...

Stray shots risk hitting the upper acoustic sensors, upper temperature sensor or their wiring. This section explains how to repair in these cases.

Repairing sensor wiring

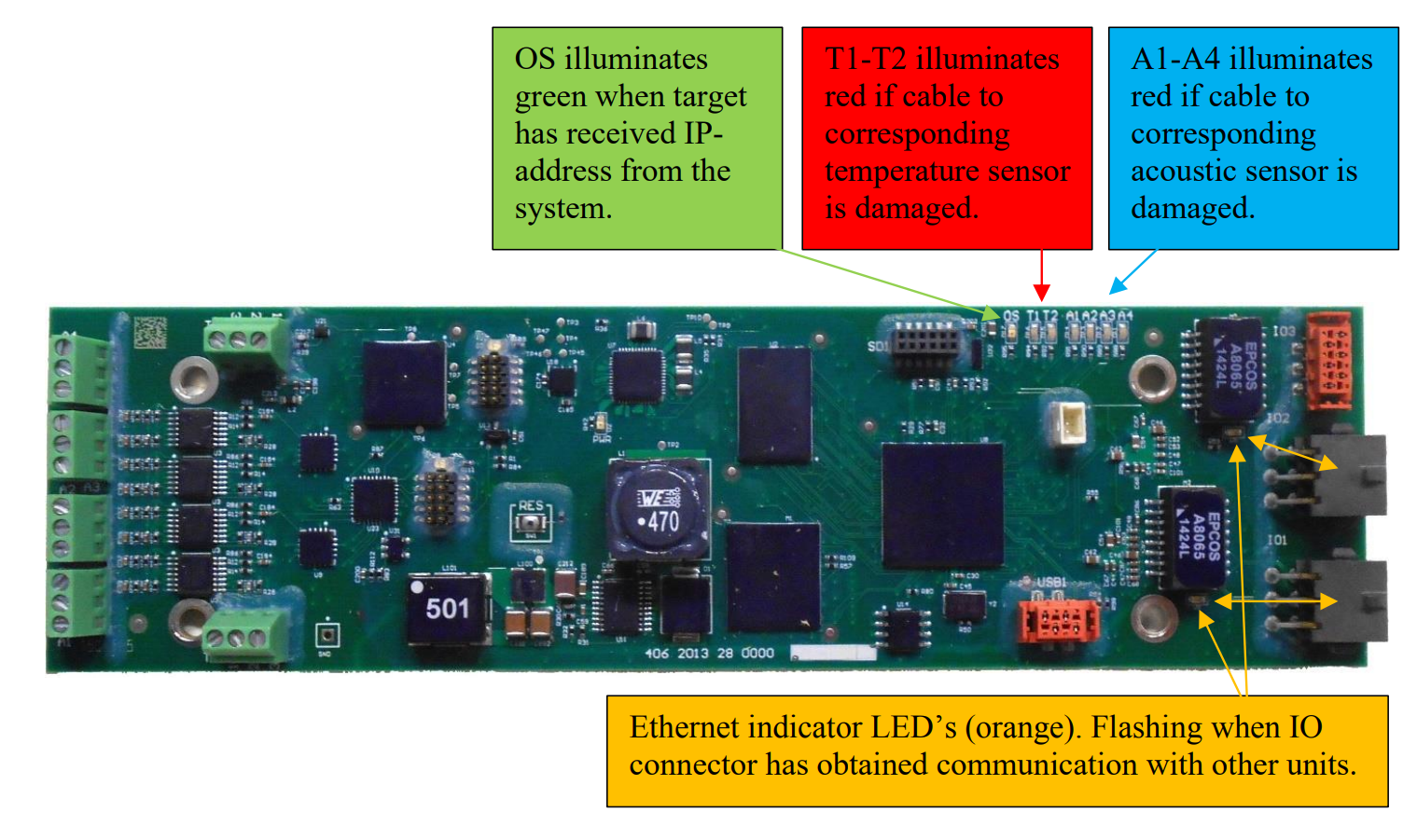

To simplify repairs, all upper sensor wirings are run on the outskirt of the target frame. In the case of a bullet or ricochet cutting a sensor cable, the target electronics will detect that something is wrong with the sensor and also provide warnings to the scoring system. Additionally the circuit board inside the target (the target electronics) will display sensor status by use of LEDs. This circuit board is accessible behind the service panel at the bottom of the target.

Sensor cables may be temporarily spliced with butt splices. However, as a permanent repair cables should be spliced by soldering and sealed with heat shrink tube - if sensor cable isn't replaced. Please also splice the un-isolated leader in the sensor cables.

Replacing sensors

In some cases it might be easier or necessary to replace the entire sensor with wiring harness.

The sensor wires are attached to their respective numbered terminal blocks according to the tables below:

| Connector No. | Attached sensor |

| A1 | Upper right acoustic sensor |

| A2 | Lower right acoustic sensor |

| A3 | Lower left acoustic sensor |

| A4 | Upper left acoustic sensor |

| T1 | Lower temperature sensor |

| T2 | Upper temperature sensor |

The teminal blocks are found at the left side of the board (green components at the image above). Teminal block A1 is the lower left, followed by A2, A3 and the A4 is the upper left block. Each connection point of each termainal block are individually numbered 1, 2 and 3.

For sensors A1-A4 the sensor cable is connected to the terminal blocks as follows:

| Wire | Connection point |

| Red | 1 |

| Black | 2 |

| Cable screen / Ground | 3 |

For sensor T2 the sensor cable is connected to its teminal block as follows:

| Wire | Connection point |

| White | 1 |

| Black | 2 |

| Cable screen / Ground | 3 |

For sensor T1 the sensor cable is connected to its terminal block as follows:

| Wire | Connection point |

| Red | 1 |

| Green | 2 |

| Yellow | 3 |

Replacing the upper acoustic sensors

If the upper sensors are to be replaced a section (corner) of the target rubber skin must be detached the target frame to access the sensor(s). We recommend accessing from the front of the target. The acoustic sensors are taped to an aluminum bracket that is screwed into the target frame.

Upper right acoustic sensor mounted on aluminum bracket. The upper right temperature sensor is also visible.

Upper right acoustic sensor mounted on aluminum bracket. The upper right temperature sensor is also visible.

Use the same screws and screw holes when replacing the sensor.

The temperature sensor is supposed to extend only 2-3 cm inside the target frame.

Replacing I/O cables

I/O cables are pre fabricated to specific lengths. The male and the female I/O cables are connected to the target electroniscs IO1 and IO2 box connectors at the right side of the board. Also, cable ground wires are screwed to the metal of which the target electronics is attached.

When ordering I/O cables make sure to choose the connector series fitting rest of the system. See exploaded view parts list at top of this user manual to find part numbers.

I/O cables are attached to target frame with cable clamps and a and some adhesive tape. Install the cables as the original cable harness. Get some cable ties before replacing cables, in addition to canvas tape.

I/O cables are always put in a loop inside target, to obtain maximum strain relief. Prevent loop from touching any nearby sensors by bending the loop in combination with using cable clips. Images below from different target models:

|

|

I/O cables should extend approximately 14cm from the underside of the target frame.

Protecting the H3H Target

How to protect the target from stray bullets and ricochets

Protecting the eScore acoustic target

The eScore targets have the critical electronics located at the bottom of the tar

The targets have the most critical, or all, electronic components located at the bottom of the target - behind the service panel. To minimize maintenance cost and maintain the target durability it is recommended to protect this section of the target by use of a knee wall or protective plates. Target stands with protective plates are available on request.

Please refer to this YouTube video for recommendations on how to install the targets.

Protection from ricochets and shrapnel

Some shooting ranges have backstop that create shrapnel when bullets hit bullet catchers. This should be avoided since cables may be cut or short circuited by shrapnel or bullet jackets. To minimize the effects careful placement of the wiring between targets, antennas, batteries etc. must be done. If steel bullet catcher is used, make sure to cover it with rubber material or other absorbent material to minimize ricochets and shrapnel exiting the bullet catcher.