Introduksjon OpticScore eScore

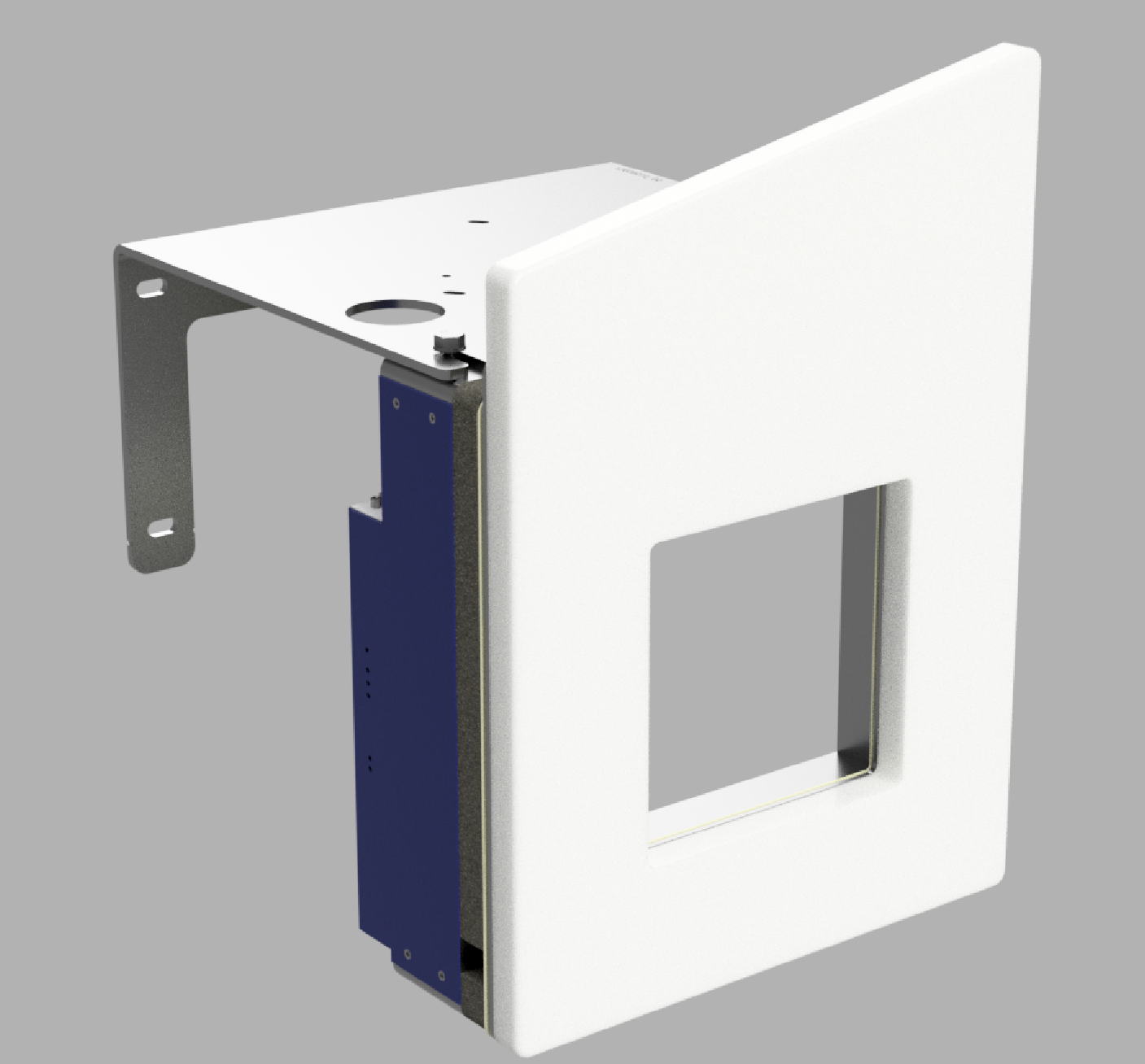

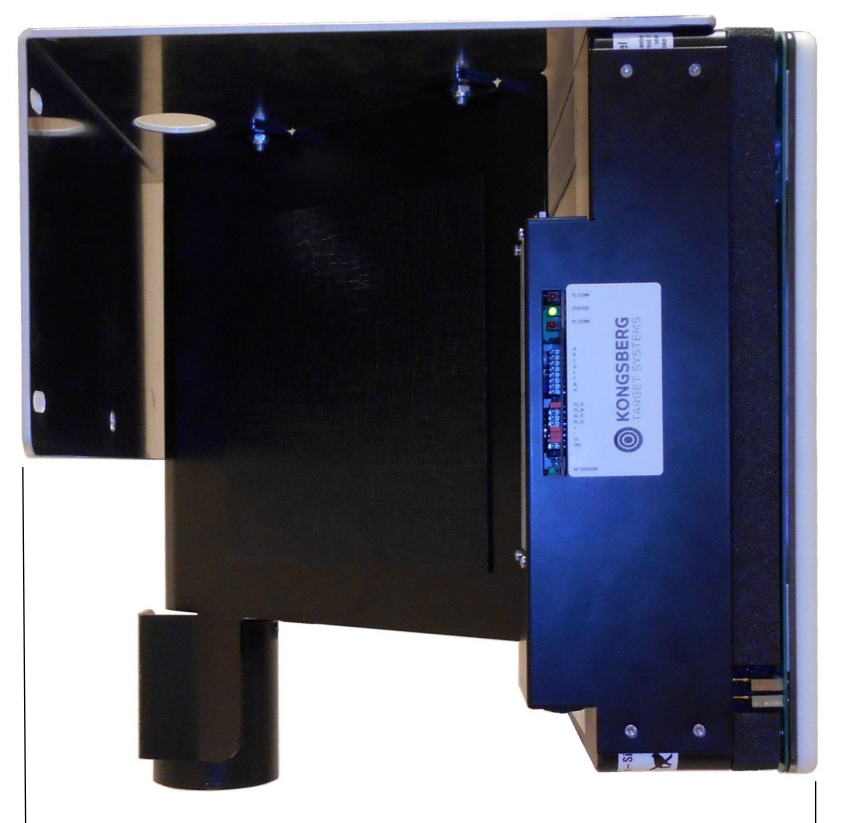

eScore OpticScore-målet er neste generasjons elektronisk målsystem med optisk deteksjonsteknologi. Kameraer inne i målet registrerer kulen presist. Målet anbefales for innendørs skytebaner og for bruk med luftgevær, luftpistoler og kaliber .22LR rifler er tilgjengelige. Målet kan leveres med målløfter, som gir mulighet for forskjellige skytehøyder (knelende, stående og magestilling). LED-belysningen kan justeres av skytteren, noe som gir optimal lysstyrke og fargevalg for alle skyteforhold og personlige preferanser.

Funksjoner for eScore OpticScore

Presis deteksjon – Deteksjonsrammen har en ISSF fase 1-godkjenning.

Passer for kortdistanse (10–15 m) .22LR og luftgevær.

Liten størrelse, rask oppsett

Bredt utvalg av målpoengdefinisjoner og maskemål tilgjengelig

Enkelt å bytte ut maskemål

Lavt vedlikehold

Målløft tilgjengelig

Justerbar belysning (intensitet og fargevalg)

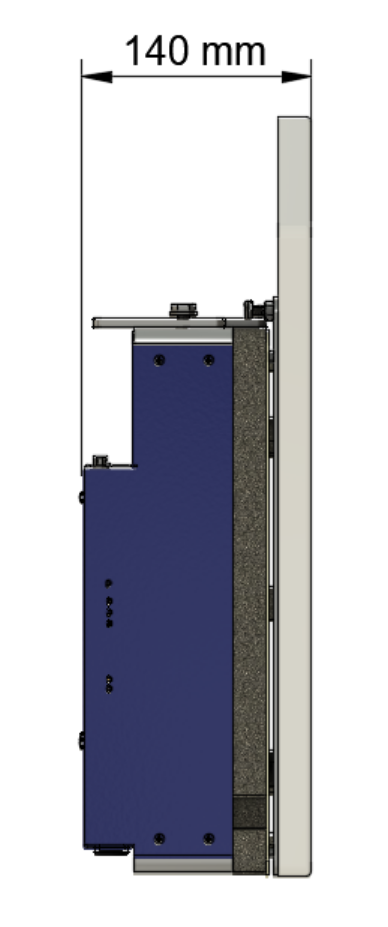

Tekniske spesifikasjoner og dimensjoner

| Temperaturområde | 0 til +40 °C |

| Vekt | 3,5 kg (kun Target) 8 kg (mål med beskyttelsesplate) 13,5 kg (målløft) |

| Strømforbruk | ~ 17 W @ 24 VDC (med maks belysning) ~ 50 W @ 24 VDC (Målløft beveger seg oppover, belysning på) |

| Godkjente kalibre | 4,5 mm luftgevær og .22LR rifle |

| Anbefalt bruk | 10–15 m luftpistol/luftgevær 10–15 m .22LR rifle |

| Anbefalt driftsspenning | Typisk 24 V (Kan fungere i området 12V–48V) |

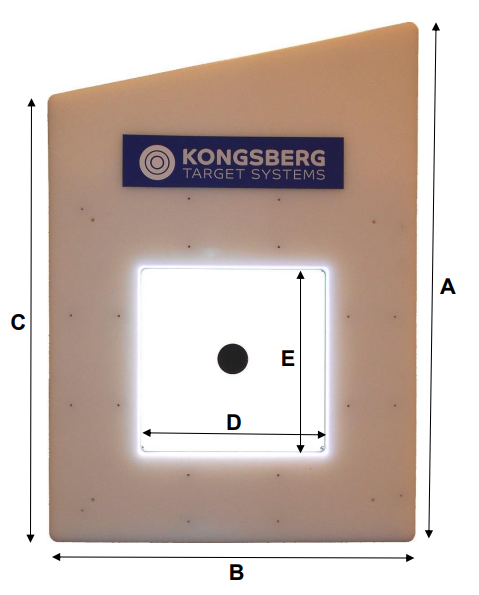

Dimensjoner

| A: 470 mm |  |

|

| B: 400 mm | ||

| C: 330 mm | ||

| D: 170 mm | ||

| Ø: 170 mm |

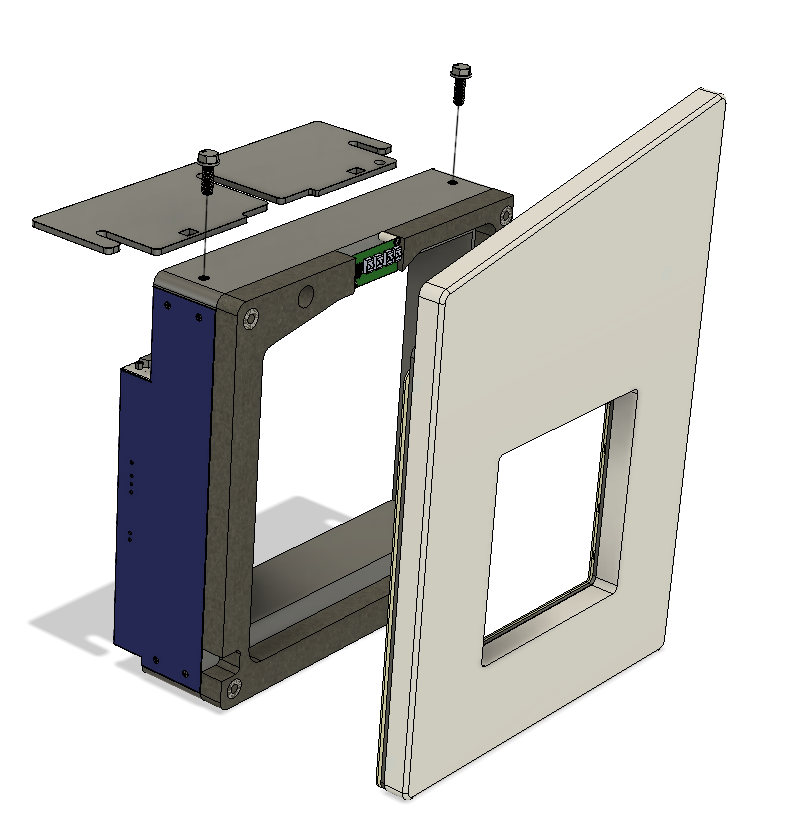

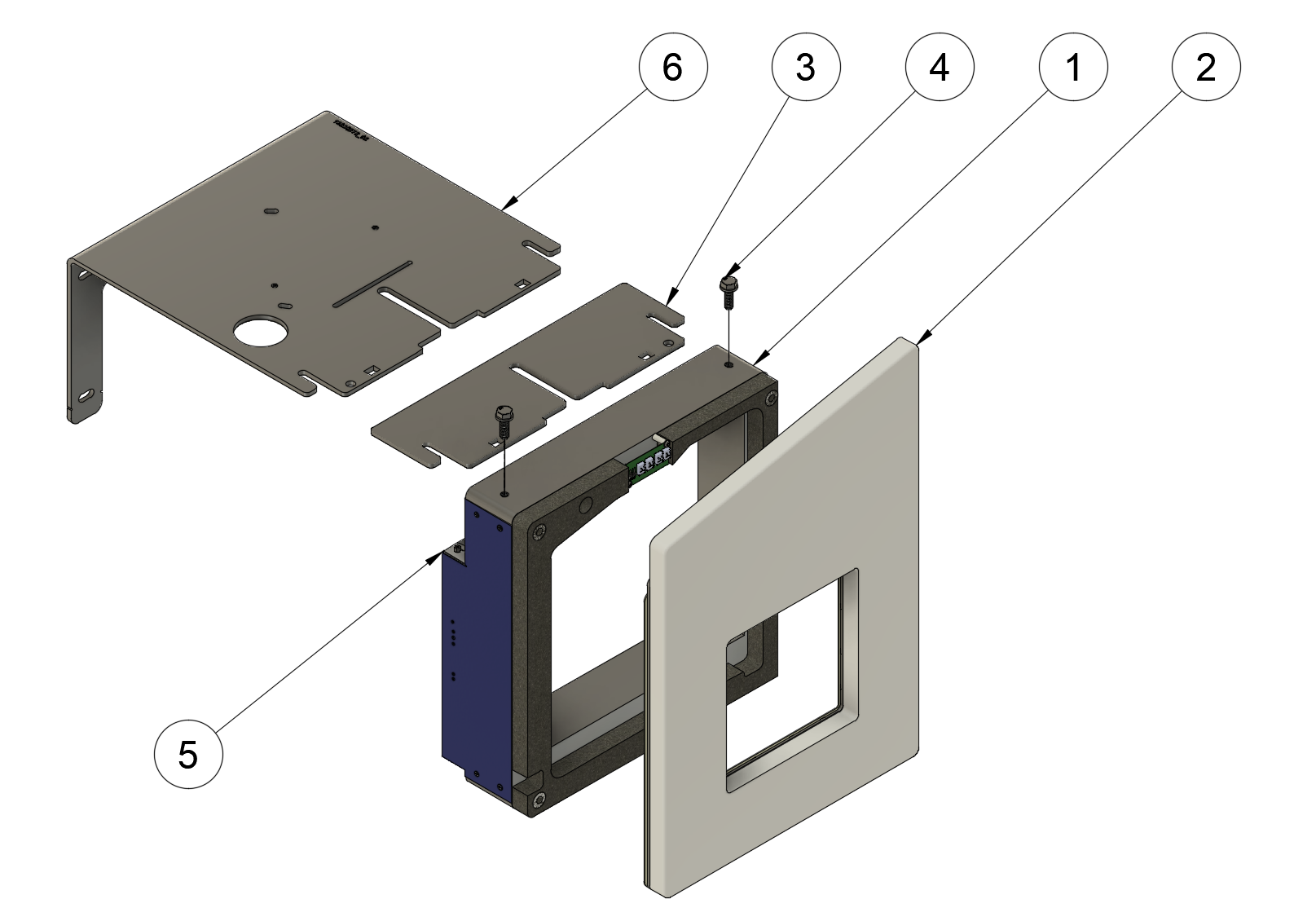

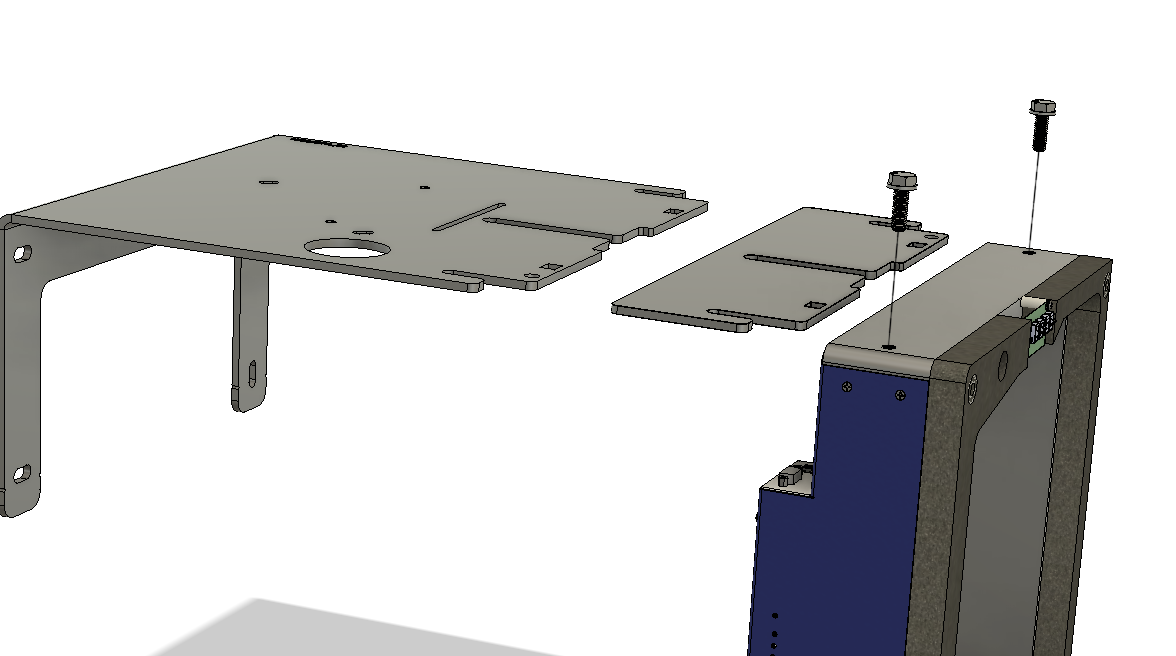

eScore OpticScore exploded view and partslist

Exploded view Below is an exploded view of the common components used in the eSco...

Exploded view

Below is an exploded view of the common components used in the eScore OpticScore target

Part list

| ID | Description |

| 1 | eScore OpticScore Target |

| 2 | Protection plate with illumination |

| 3 | Illumination bracket |

| 4 | Mounting screws and washer (M8) |

| 5 | eScore OpticScore Target electronics housing (wiring not shown)- options with different connectors are available |

| 6 | Optional: Wall mount / bullet catcher bracket |

Tilgjengelige maskemål for OpticScore

Available mask targets for OpticScore

The OpticScore target can be fitted with different mask targets:

| KTS part number: | Name | Spot size |

| 97020797 | ISSF 10m air rifle | Ø 30.5mm |

| 97020798 | ISSF 10m air pistol | Ø 59.5mm |

| 97020810 | DFS 15m rifle | Ø 38mm |

| 97020848 | NSF 15m rifle | Ø 34.2mm |

| 97020879 | DGI 15m air rifle | Ø 42.75mm |

| 97020880 | DGI 15m pistol | Ø 100mm |

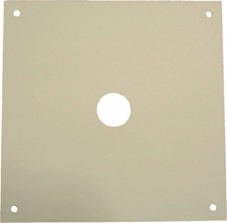

The target may also be fitted with a black cardboard backer / witness plate (KTS part no: 97020801).

Vedlikeholdskrav for eScore OpticScore

Selv om eScore OpticScore-målet er så godt som vedlikeholdsfritt, kan miljøet på og rundt mållinjen være utfordrende med tanke på rusk fra kuler og papirmaskemål. Dette medfører noe mindre vedlikehold som bør gjøres for å bevare optimal nøyaktighet for dette optiske målet.

Merk : Vær svært forsiktig så du IKKE berører speilene eller glasset i målet når du håndterer OpticScore-målet. Fingeravtrykk, riper eller andre skader på de optiske deteksjonsflatene godtas ikke som garantikrav. Observer og følg anbefalingene knyttet til rengjørings- og håndteringsprosedyrene i dette kapittelet nøye, inkludert å IKKE blåse støv og papirrester ut av målet manuelt (med munnen).

Bytte ut maskemål

Det finnes en rekke maskemål tilgjengelig for dette målet. Når det skytes ut (treff utenfor det "svarte" området etterlater et kulehull) - eller brukeren ønsker å endre maskemålet til en annen måldefinisjon.

Nødvendig verktøy: Ingen

Nødvendig utstyr: Nytt målskive, mikrofiberklut

Trinn 1:

Ta av beskyttelsesplaten . Beskyttelsesplaten henger på belysningsbraketten eller kulefangeren/veggmonteringsbraketten med to M8-skruer med panhode festet i beskyttelsesplaten. Bare vipp bunnen av beskyttelsesplaten bort fra målet til magnetene løsner, og løft deretter opp beskyttelsesplaten.

Sørg for at komponentene på baksiden av beskyttelsesplaten ikke blir skadet ved å plassere den på en flat og stabil overflate mens du arbeider på målet.

Videoen nedenfor viser de anbefalte bevegelsene for demontering av beskyttelsesplaten.

Trinn 2:

Fjern den gamle masken og resirkuler den

Trinn 3:

Fjern eventuelt rusk om nødvendig – se neste kapittel for retningslinjer

Trinn 4:

Sett inn det nye maskemålet fra forsiden av målet. Bruk de fire hullene i hjørnene på det nye maskemålet og fest det på de fire skruene inni målet. Skruene er laget litt fleksible for å kunne stramme opp maskemålet.

Det er av største betydning at maskemålet er helt rett etter installasjon. Et bøyd maskemål kan forstyrre det optiske målefeltet.

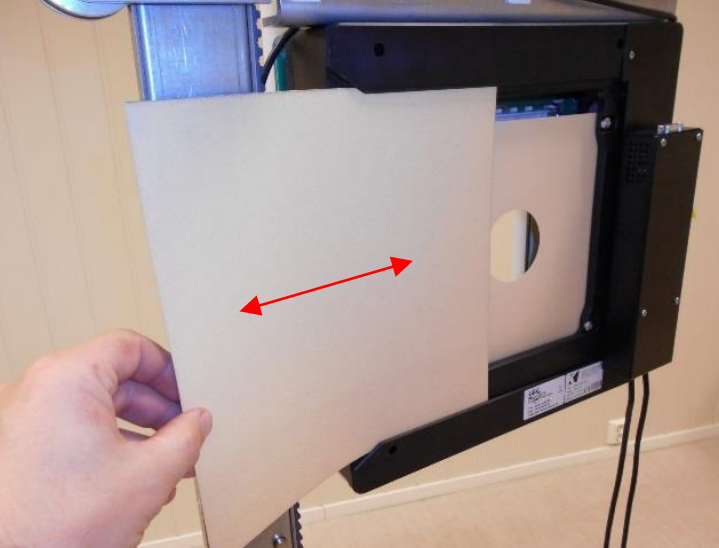

Hvis du bruker svart bakgrunn eller bekreftelsespapir

Et nytt bakgrunns-/verifiseringspapir kan installeres ved å skyve det inn/ut fra baksiden av målet som illustrert:

Trinn 5:

Sett beskyttelsesplaten på plass igjen. Vær forsiktig så du ikke skader komponentene på baksiden! Se videoen nedenfor for en illustrasjon av hvordan du monterer platen riktig.

Kontroller at belysningen lyser etter montering av målfronten!

Dette kan ta noen sekunder etter at den er slått på. Hvis belysningen ikke har tent etter 30 sekunder, må du bekrefte at det er strøm på målet ved å inspisere OS-LED-en på siden av målet. Hvis strømmen er på og belysningen er av, kan du prøve å klemme beskyttelsesplaten mot målrammen.

Kritiske overflater, fjerning av rusk eller partikler

Advarsel

Pass på at du ikke skader speilene eller glassplatene inni målet! Fingeravtrykk eller riper vil redusere nøyaktigheten!

Papirpartikler eller annet rusk på overflatene inne i målet kan redusere nøyaktigheten. Det anbefales derfor å fjerne rusk når du bytter ut siktereferansen. Dette bør gjøres med lett trykkluft.

Advarsel

Kompressortrykkluft skal ikke brukes, og det skal IKKE blåses luft manuelt! Dette kan etterlate rester av kompressorolje eller spytt som vil korrodere på speiloverflatene.

En luftblåser for kameralinsen bør brukes. Den etterlater ikke rester eller har for høyt trykk:

Speilene er forsølvet. Rengjøring av speilene bør kun gjøres når det er nødvendig for å bevare egenskapene deres. Hver rengjøring vil føre til mindre slitasje på speiloverflaten.

Ved rengjøring av speil og glassflater bør følgende vurderes:

- Fjern papirpartikler forsiktig med luft (se verktøyet ovenfor)

- Tørk forsiktig bort gjenværende rester med en ren mikrofiberklut

- Om nødvendig kan en fuktig mikrofiberklut brukes, men fuktighetsrester på overflatene må unngås.

Synlig korrosjon på speiloverflatene

Hvis det er synlig korrosjon eller annen forurensning på speilet, kan en IKKE-SLIPENDE sølvpleiekrem brukes til å polere det. Vær svært forsiktig og ikke bruk for mye kraft!

Sørg for å følge prosedyrene ovenfor, og sørg for å rengjøre alle rester etter bruk.

KTS kan levere eller anbefale et passende sølvpleieprodukt på forespørsel.

Rengjøring eller behandling av speil anbefales ikke med mindre det er synlig forurensning.

Krav til lagring

Storage of OpticScore target

The eScore OpticScore target must be stored in a clean and dry environment (<50% humidity) above 10 °C. If there is a high degree of particles in the air or environment in storage, the target should be covered so that the glass and mirror surfaces in the target is not exposed to a high degree of contamination.

Legg til utstyr

Det finnes en rekke tilleggsutstyr som kan bestilles med OpticScore - eScore-målet. Disse er listet opp her:

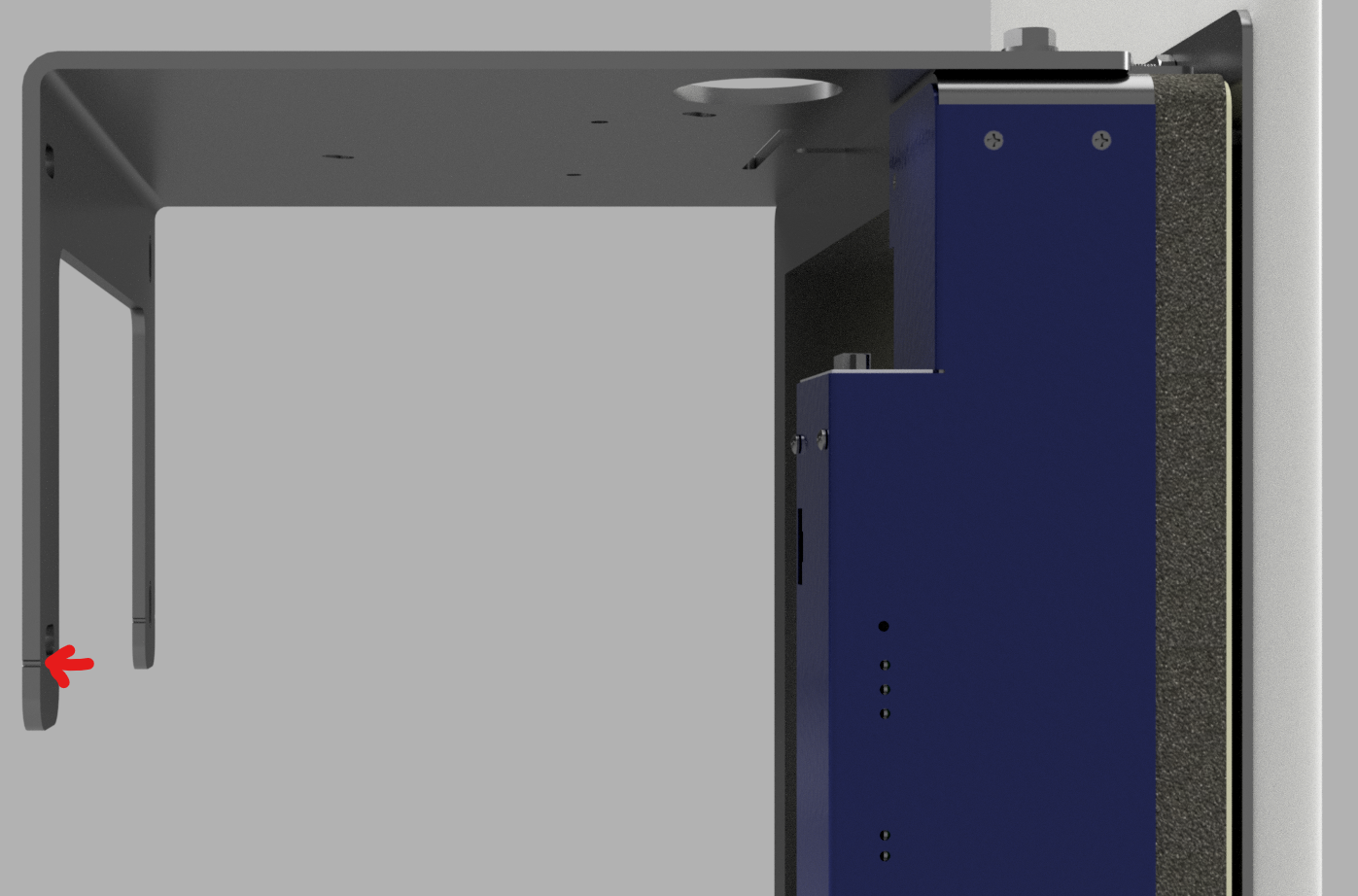

Veggfeste / kulefangerbrakett

eScore opticScore har et veggmonteringsbrakett tilgjengelig, som også kan fungere som et feste for kulefangeren for luftgevær. Braketten har et senterlinjemerke som er på linje med midten av målet (i høyden). Dette er nyttig når du justerer mål med en bestemt høyde på skytebanen. Braketten leveres med fire hull på baksiden, for skruer som kan brukes til å feste målet til veggen. Bruk en boblenivåer eller lignende når du monterer braketten på veggen for å sikre horisontal aksejustering.

Det må være en kulefanger bak veggen for å bruke veggfestet uten kulefanger til luftgevær.

Tupp!

Fest veggfestebraketten til veggen før du fester målet til braketten.

Vær oppmerksom på at denne braketten alltid brukes når du bruker kulefangeren til luftgeværet, selv om målet ikke er montert på en vegg (dvs. mål brukt med målløfter).

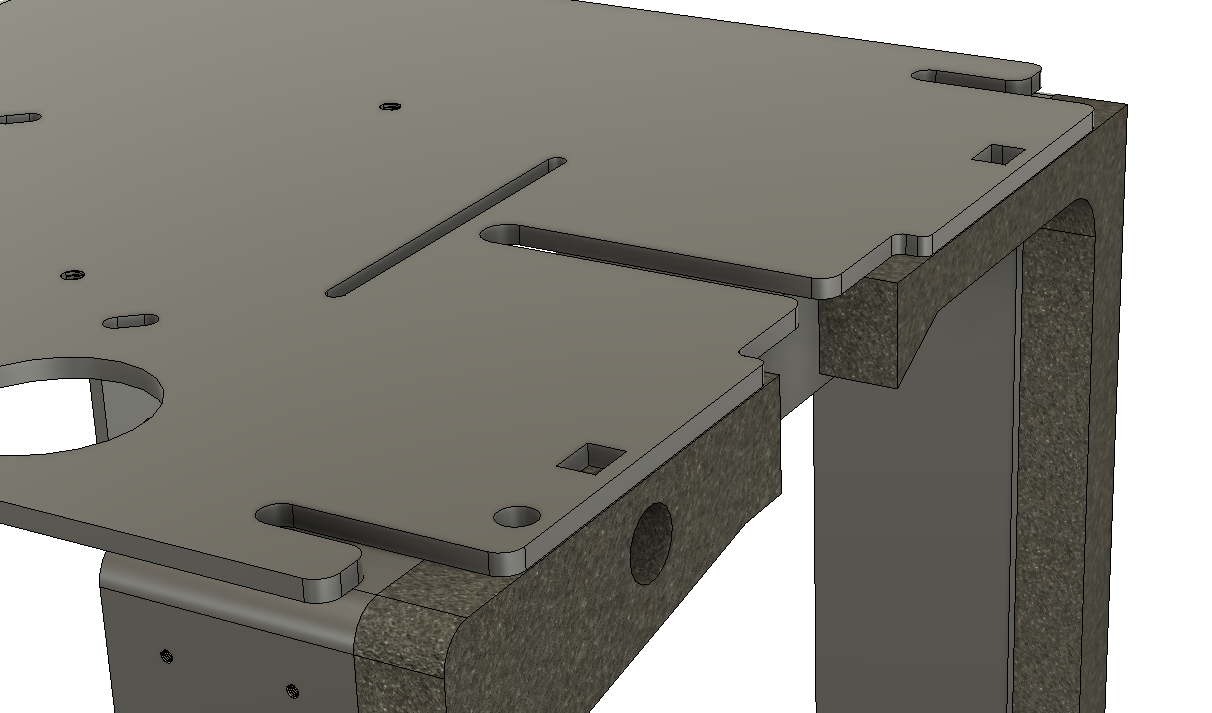

Veggfestet/kulefangerbraketten festes til målet på følgende måte:

- Fjern beskyttelsesplaten (se vedlikeholdskapittelet for veiledning)

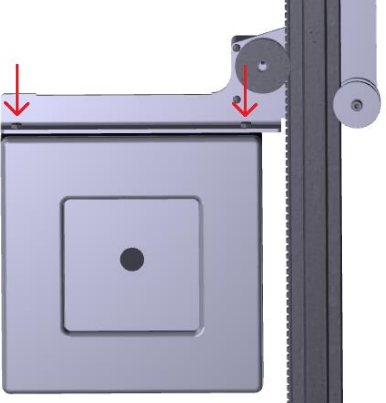

- Løsne de 2x M8 sekskantskruene på toppen av målet litt.

Merk at hvis målet er festet til en målløfter eller et veggfeste, må ikke disse boltene løsnes helt! Dette kan føre til at målet faller ned og knekker.

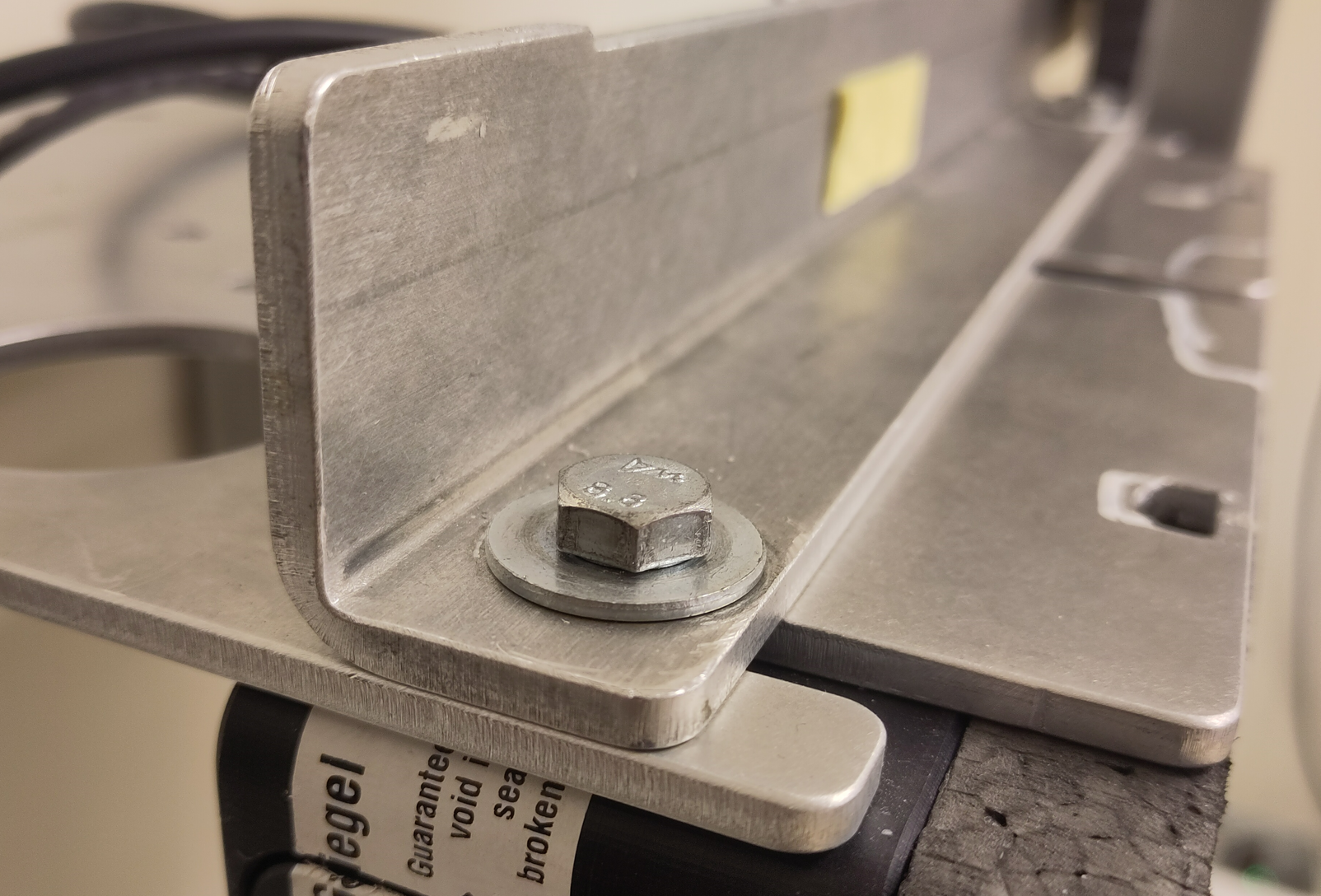

- Bytt belysningsbraketten med veggfestebraketten – sørg for at skivene er plassert oppå braketten og ikke under.

- Stram skruene (ikke bruk for mye kraft!)

Note!

Sørg for at målet er skjøvet helt inn i sporet på braketten.

- Monter beskyttelsesplaten igjen (se vedlikeholdskapittelet for veiledning).

4,5 mm kulefanger for luftgevær

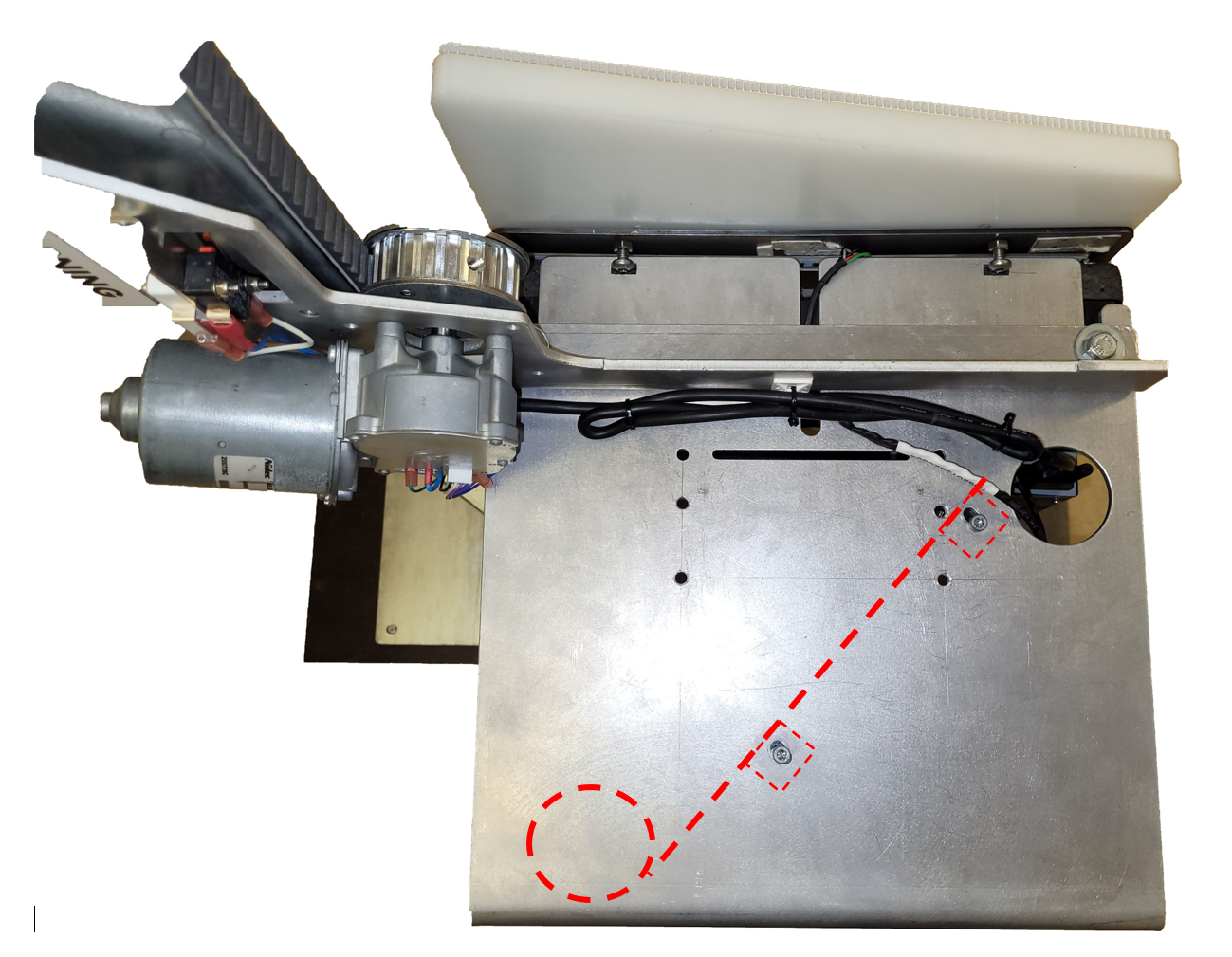

En valgfri kulefanger for luftgevær er tilgjengelig, KTS delenummer 33 07 004 – merk at du må ha veggfeste/kulefangerbrakett (KTS delenummer 13020272) for å kunne montere kulefangeren riktig på målet. Braketten kan også brukes med målløftere. Kulefangeren må festes til braketten. Bruk de medfølgende mutterne og boltene, som vist på illustrasjonene nedenfor.

Advarsel!

Denne kulefangeren må IKKE skytes på med andre kuler enn luftgeværhagler i kaliber 4,5 mm.

Merk at målet som brukes på bildet ovenfor er en annen målmodell, men bildet illustrerer hvordan kulefangeren er festet til braketten. Bildet nedenfor illustrerer også hvordan kulefangeren er plassert inne i braketten (røde stiplede linjer).

Beskyttelsesplate for rikosjett av luftgevær

Luftgeværkuler kan sprette tilbake mot skytterens posisjon hvis de bommer på treffpunktet og treffer målbeskyttelsesplaten. For å forhindre dette kan en rikosjettbeskyttelsesplate (KTS delenummer 97020813) festes til målbeskyttelsesplaten. Den er festet med fire plastknapper (KTS delenummer 1507002).

Denne platen kan ikke håndtere et begrenset antall skudd, og må kanskje byttes ut når den ytre overflaten er degradert. Pellets fanges opp inne i platens ytre overflate.

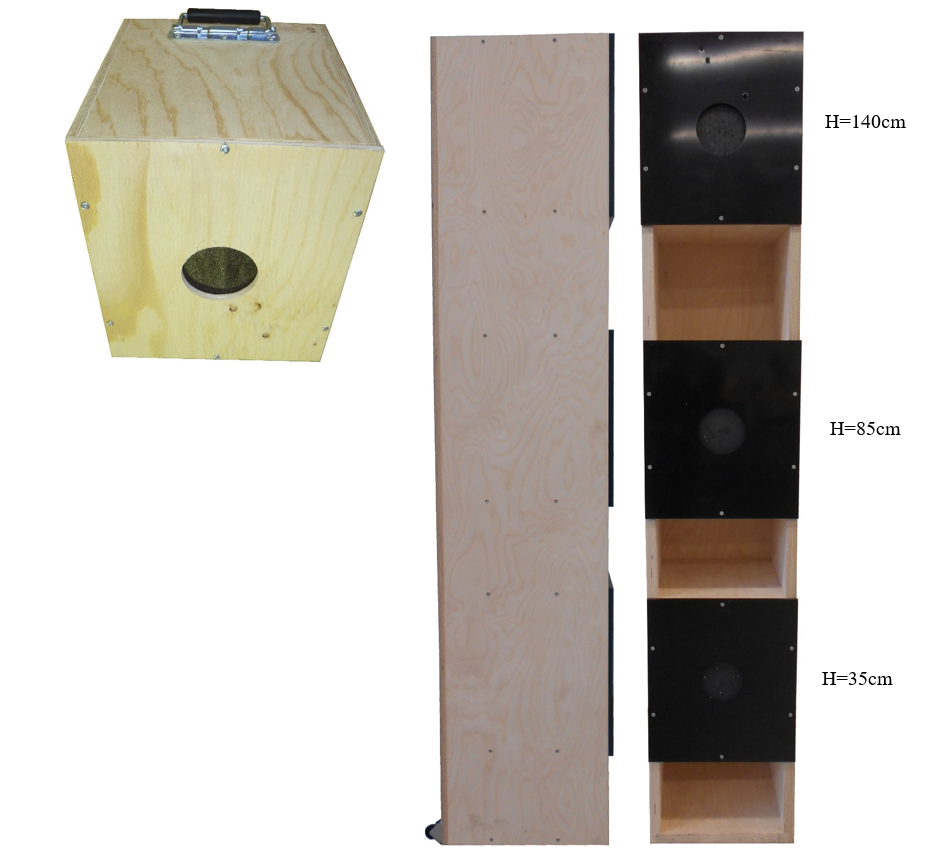

Målløft

eScore OpticScore Target Lift

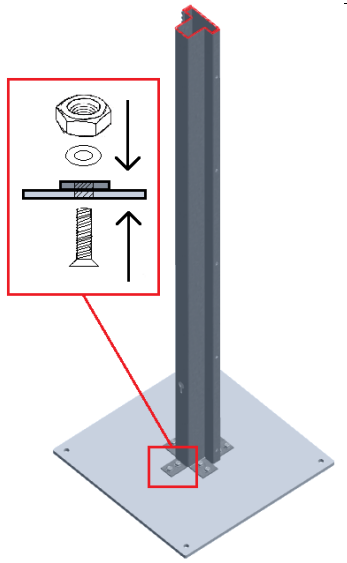

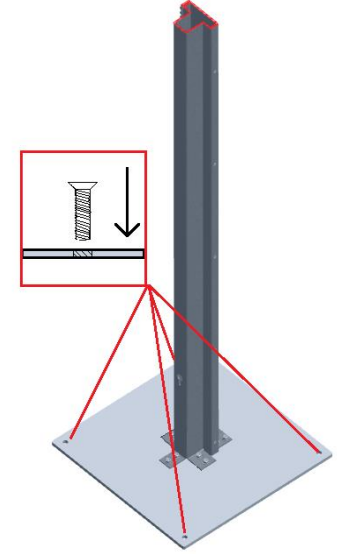

Target lifts are available for the opticScore eScore target. Some assembly is required on the range on first time use and this is described here.

Assembly instructions

| Mount the bottom plate to the lifter spine with the included nuts, bolts and washers |  |

|

Mount the bottom plate to the floor (or other suitable platform) with appropriate fasteners for the selected material Warning!This has to be done prior to mounting the target to the target lift!

|

|

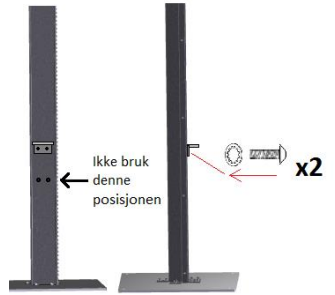

| Mount the end-stop bracket with two screws and spring-washers. Use the upper position, NOT the lower. |  |

|

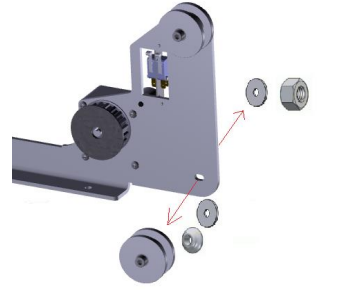

Remove the lower support wheel from the lift bracket. Assembly infoRemember the orientation of the conical washer that is assembled next to the bearing inside the support wheel. This washer must be inserted in the same orientation and the same sequence in relation to the other washers

|

|

|

Rotate the lifter bracket and insert it onto the lifter spine. Rotate it counter clockwise so that the gear and support wheels support the lifter bracket. Assembly infoMount the lower support wheel, but do not tighten the screws (Yet)

|

|

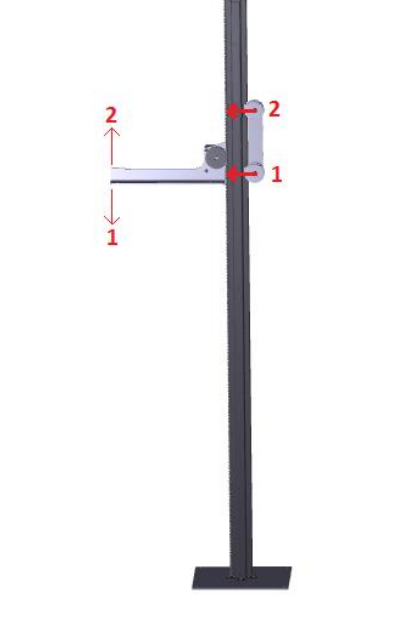

The bracket shall now be approximately 90 degrees in relation to the spine. Adjust the support wheels as appropriate if necessary. Assembly warningDo not over-tighten the screws on the support wheels as the bearings might be damaged.

Assembly tipIt is required to be two persons while performing this step.

|

|

|

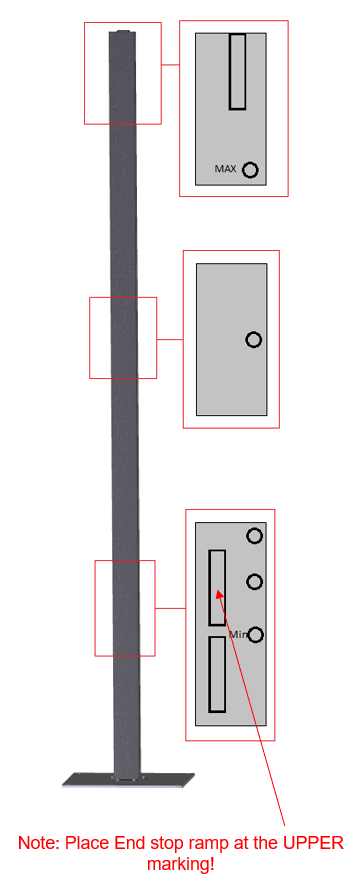

Install end-stop triggers at the lifter spine

Remove the protection on the two-sided tape on the back of the end-stop triggers. (Two in total)  Tape the triggers to the rectangular marks at the the lifter spine indicated by the drawing to the right. One at top of the spine, and two at the bottom. Don't mind the round marks. Please noteNote that on the lower end of the lifter spine, there are two rectangular marks. Use the upper one, indicated at the drawing!

|

|

| This figure shows the end-stop triggers and bracket in place. Don't mind the small circles. |  |

|

The target is now joined with the lifter bracket by the use of the two M8 bolts and washers (at top of target). Leave a small gap between the target frame and lifter bracket.

If the airgun bulletcatcher is used (thus using the bullet catcher bracket), then replace the supplied illumination bracket with the bullet catcher bracket in the above mentioned gap. Push it all way forward, until it rests against the screws.

Else, keep the illumination bracket in the mentioned gap. Push it all way forward, until it rests against the screws.

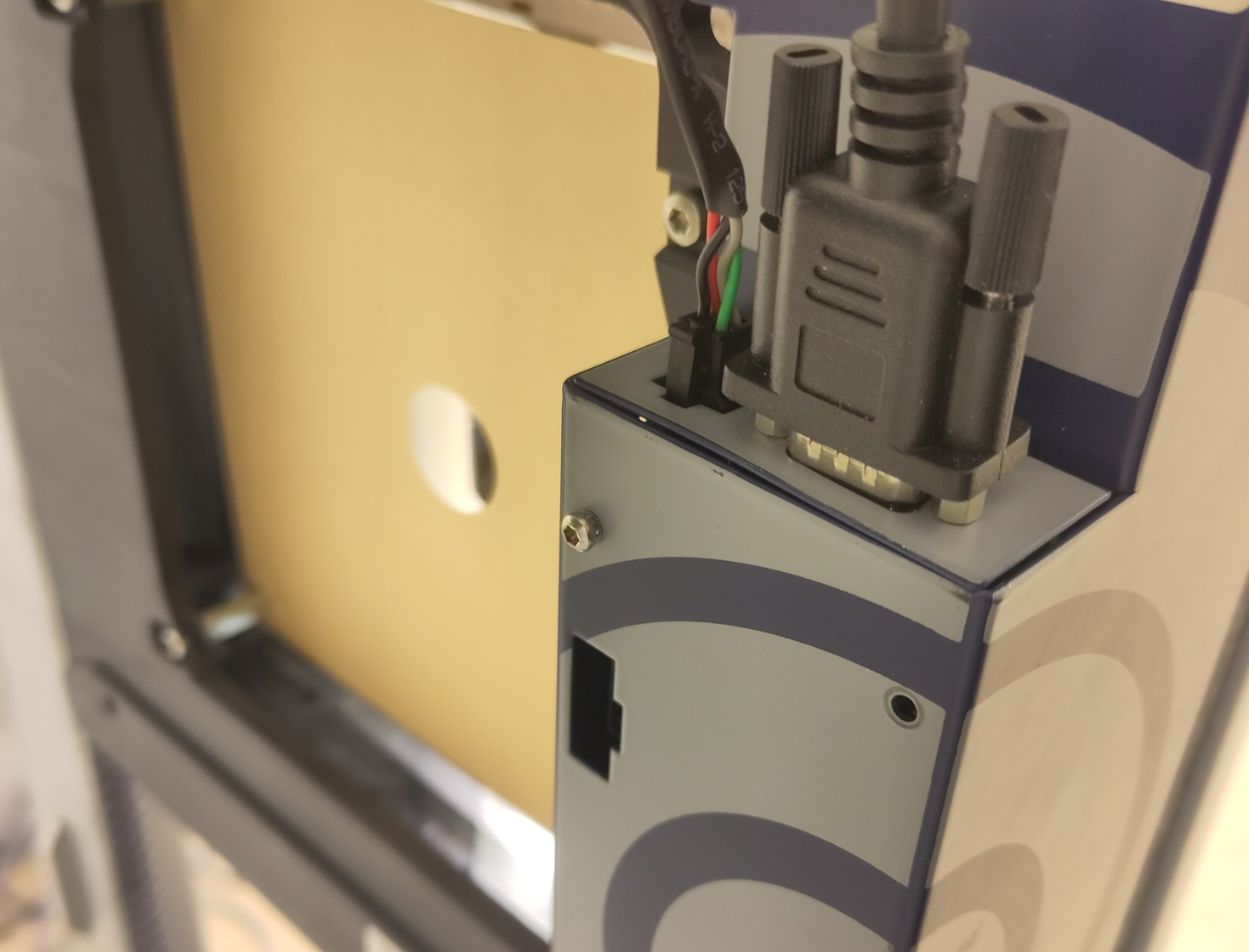

Note!Ensure that the Illumination cable is placed in the groove in the bullet catcher / illumination bracket. Tighten the two screws at the top of the target, that joins all brackets and target together. Do NOT overtighten these screws as the target will be damaged. |

|

|

The cable from the lifter bracket motor is connected to the opticScore target. The illumination cable is also connected to the target. Image to the right shows both cables connected. |

|

Rikosjettbeskyttelse for målløft

KTS delenummer 117 0097 44 0024.

Produktet dekker løftestangen. Brukes kun ved skyting med kaliber .22LR. Dette produktet fungerer som en formell rikosjettbeskyttelse, og reduserer også skader på løftestangen hvis den blir truffet av løse skudd.

Ricochet-beskyttelsen henges bare i nøkkelhullene på forsiden av løftestangen. Første montering inkluderer montering av de tre medfølgende skruene på baksiden av Ricochet-beskyttelsen. Det er forhåndslagde hull for skruene.

Kulefangere av gummigranulat

Kulefangere av gummigranulat (KTS-delenr. 107 0097 24 0042) og kulefangere av gummigranulat for 3-posisjonsskyting (KTS-delenr. 107 0097 24 0049) finnes også. Disse kulefangerne er hovedsakelig beregnet for kuler i kaliber .22LR. De bør ikke brukes til kraftigere kalibre.